News and articles

- Home

- Articles

Latest posts

A gardening assistant works with establishing, maintaining, and caring for green environments such as parks, gardens, residential areas, and public spaces. Tasks include planting flowers and shrubs, mowing lawns, pruning, weed control, and watering. The work also involves using various machines and tools, as well as collaborating with others in the gardening industry. The work environment is often outdoors and varies with the seasons, requiring good physical fitness and adaptability.

Read more ->

A landscape architect plans, designs, and creates outdoor environments such as parks, gardens, courtyards, and public spaces. Tasks include drawing and designing green spaces, selecting plant materials, creating sustainable solutions, and coordinating projects with other professionals like construction engineers and urban planners. The work often takes place both at the office, where drawings and models are developed, and on-site for follow-up and implementation. The work environment is diverse, involving both creative and technical elements, with much contact with clients, contractors, and authorities.

Read more ->-

Opinion Poll: Demoskop February 2026 – Center increases, S still largest

Fri, 27 Feb 2026 - 09:35 -

Policy rate remains at 1.75% – Riksbank signals stability

Thu, 29 Jan 2026 - 14:02

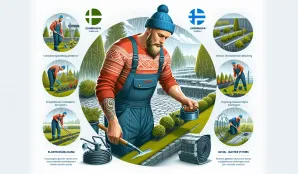

A gardening worker is responsible for planting, pruning, weeding, fertilizing, and maintaining plants and green spaces in parks, gardens, and public areas. Tasks may also include laying lawns, paving, watering, and working with garden machinery. The work is primarily outdoors and often physically demanding, meaning weather and season significantly impact the work environment. The role requires good planning, teamwork skills, and an eye for detail to create pleasant and sustainable outdoor environments.

Read more ->

A gardening construction worker is responsible for creating, developing, and maintaining outdoor environments such as parks, gardens, courtyards, and public green spaces. Tasks often include land work, paving, planting shrubs and trees, laying turf, and maintaining walkways and green areas. The work is primarily outdoors and involves physically demanding tasks and machine operation. The work environment varies depending on the project and season but often involves teamwork and adaptation to weather conditions.

Read more ->

A garden landscaper is responsible for creating and maintaining outdoor environments such as parks, gardens, courtyards, and green areas at public and private properties. Tasks include groundworks, planting of flowers and trees, paving, drainage, excavation, pruning, and maintenance. The work is mostly outdoors and involves physically demanding tasks as well as significant machine operation. Garden landscapers often work in teams, but independent work is also common, especially for smaller projects or specific area maintenance.

Read more ->

A tree feller is responsible for felling, pruning, and handling trees in various environments, from dense forests to residential plots and urban areas. The work includes planning the felling, securing the area, using chainsaws, climbing trees, and sometimes working with specialized equipment for sectional felling or removing hazardous trees. The work environment is often challenging and requires good physical condition, as work is performed outdoors in varying weather, sometimes at great heights and on uneven terrain. Safety routines are crucial, and collaboration with other professionals such as arborists and ground workers is common.

Read more ->

A trader works with buying and selling financial instruments such as stocks, currencies, commodities, or derivatives on behalf of banks, investment firms, funds, or larger companies. The tasks involve analyzing market data, following global economic news, and making quick decisions about trades, often under time pressure. The environment is characterized by a fast pace, advanced IT systems, and a requirement for constant presence during market hours. Work is usually carried out in open-plan offices or on trading floors, where collaboration with analysts and other traders is essential for responding effectively to market changes.

Read more ->

A wire drawer primarily works with processing and shaping metal wire in various dimensions and materials, usually within the steel and metal industry. The work often takes place at machines where raw materials are fed in and drawn out to the desired thickness and length. It may also include monitoring machine functions, quality control, as well as basic maintenance and troubleshooting. The work environment is characterized by industrial settings with high noise levels and demands for precision, where safety routines are central to minimizing accident risks.

Read more ->

A timber worker in pallet manufacturing is responsible for producing, assembling, and sometimes repairing wooden pallets used for transportation and storage across various industries. The work is often performed in factories or specialized workshops, involving both manual and machine-assisted tasks. Typical duties include sawing, nailing, sanding, and inspecting materials and finished products. The work environment features a fast pace, noise, and demands for precision, while safety regulations and ergonomic tools are a natural part of daily routines.

Read more ->

A lumberjack in a sawmill plays a central role in the processing chain of timber products. Tasks mainly include handling and processing raw wood, monitoring saw machines, quality control, as well as sorting and packaging finished products. The process often takes place with large machines in noisy environments where safety procedures are crucial. The work also involves some troubleshooting during machine stoppages and maintenance, as well as collaboration with other operators to ensure a smooth production flow. The environment can be physically demanding and variable, with indoor and outdoor work depending on the season and the company's structure.

Read more ->