News and articles

- Home

- Articles

Latest posts

A certified public accountant works to review and assess the financial reporting of companies and organizations, ensuring compliance with laws and regulations. Tasks include auditing financial statements, annual reports, and financial reports, as well as providing advice on tax matters and business development. The accountant also assists in establishing internal routines and often acts as a link between management, authorities, and other stakeholders. The work environment is mainly office-based, with periods of high workload around financial closing and tax declaration times. The work involves both independent assignments and teamwork, often with regular client visits.

Read more ->

A Gnistare primarily works within the metal industry, with the main task of processing metal components using spark erosion machines, known as electrical discharge machining (EDM). The duties include setting up, monitoring, and maintaining machines used to create precise details in metal, often for industrial components, tools, or molds. The role also involves interpreting technical drawings, selecting appropriate materials and tools, and checking product quality. The work environment is usually industrial, often in larger workshops or factories, where safety and precision are highly prioritized. The work can be physically demanding and requires high accuracy and technical knowledge.

Read more ->-

Opinion Polls: Kantar-Sifo shows increased support for S, decline for SD and C

Fri, 13 Feb 2026 - 01:35 -

Policy rate remains at 1.75% – Riksbank signals stability

Thu, 29 Jan 2026 - 14:02

An incandescent lamp factory worker primarily works with assembling, inspecting, and packaging electrical components in the manufacturing process of light bulbs. Tasks often involve operating machinery, assembling parts on an assembly line, and checking that finished products meet quality standards. The work environment includes manual tasks and automated processes, requiring attention to detail, good motor skills, and teamwork. Work often occurs in shifts, and the workplace can be noisy, with potential exposure to chemicals or glass. Safety routines and ergonomics are important daily elements to prevent injuries and ensure a safe work environment.

Read more ->

Glödgare work with heat-treating metals to improve their properties, such as strength and formability. The profession involves monitoring and controlling furnaces and other technical equipment at steel and metalworks, ensuring that processes meet exact temperature and timing requirements. The work is often carried out in industrial environments where temperatures can be high, and safety routines are crucial to prevent accidents. The work environment is characterized by shift work, clear safety regulations, and close cooperation with other machine operators and technicians.

Read more ->

A glättare in paper manufacturing works on improving the surface of paper through a process where the paper web is pressed and polished to achieve desired gloss, smoothness, and thickness. Tasks include monitoring calendering machines, adjusting machine settings, and quality checks of the finished paper. The work environment involves operating large, often automated machines in industrial settings, where precision and technical interest are important qualities. Safety routines are central as work is done near moving machine parts, and collaboration with other operators and technicians is a natural part of daily work.

Read more ->

A glaze preparer mainly works with mixing, preparing, and controlling glazes used in the manufacturing of ceramics, porcelain, and glass products. The role often involves handling raw materials, weighing and dosing chemicals, and supervising machines and processes to ensure the correct composition of the glaze. The work can be performed in both small workshops and larger industrial environments, where precision and quality awareness are crucial. Glaze preparers often collaborate with other production staff and sometimes work under time pressure to maintain production pace.

Read more ->

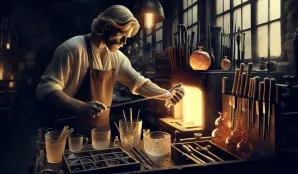

A glassworks worker is responsible for the manufacturing, processing, and refinement of various types of glass products. Tasks can include everything from melting and shaping glass at high temperatures to grinding, engraving, or decorating finished products. Work with machines to cut and process glass sheets, as well as quality control of finished items, is also common. The work environment is often warm and requires a high level of safety awareness, as work is performed near furnaces and involves handling heavy materials. Glassworks workers typically work in teams at glass factories or specialized workshops, where time pressure and precision are important aspects of daily work.

Read more ->

A glazier technician works with the installation, repair, and maintenance of glass in buildings, vehicles, and other structures where glass is an important component. Tasks include measuring and cutting glass, installing windows and facades, replacing car windows, and custom glass solutions. The work is often performed on-site at the customer's location, meaning the work environment can vary between workshops, construction sites, and private homes. Safety and precision are crucial, as work often involves working at heights or with heavy and fragile materials. Glazier technicians collaborate closely with other construction and craft professionals, and the profession requires both technical skill and good physical ability.

Read more ->

An ice cream manufacturer primarily works with producing ice cream on an industrial scale or in smaller artisanal settings. The profession includes the entire process from weighing and mixing raw materials to pasteurization, freezing, and flavoring. Work often takes place in production facilities where machines are monitored and adjusted to ensure the quality of the ice cream meets high standards. Ice cream manufacturers are also responsible for cleaning and maintaining equipment, as well as documenting processes and results. The work environment is often cool due to the low temperatures required for storage and handling of ice cream products.

Read more ->

A glass polisher works with processing, shaping, and grinding glass into various products and artworks. Tasks include following drawings and templates, using specialized tools and grinding machines to create precise shapes and patterns on glass surfaces. The work often takes place in small workshops or studios, where environment demands both accuracy and patience due to the fragility of glass and the precision of the work steps. Glass polishers often collaborate with designers, artists, or industrial manufacturers, and the profession requires both artistic sense and technical skill to ensure the final result is durable and aesthetically pleasing.

Read more ->